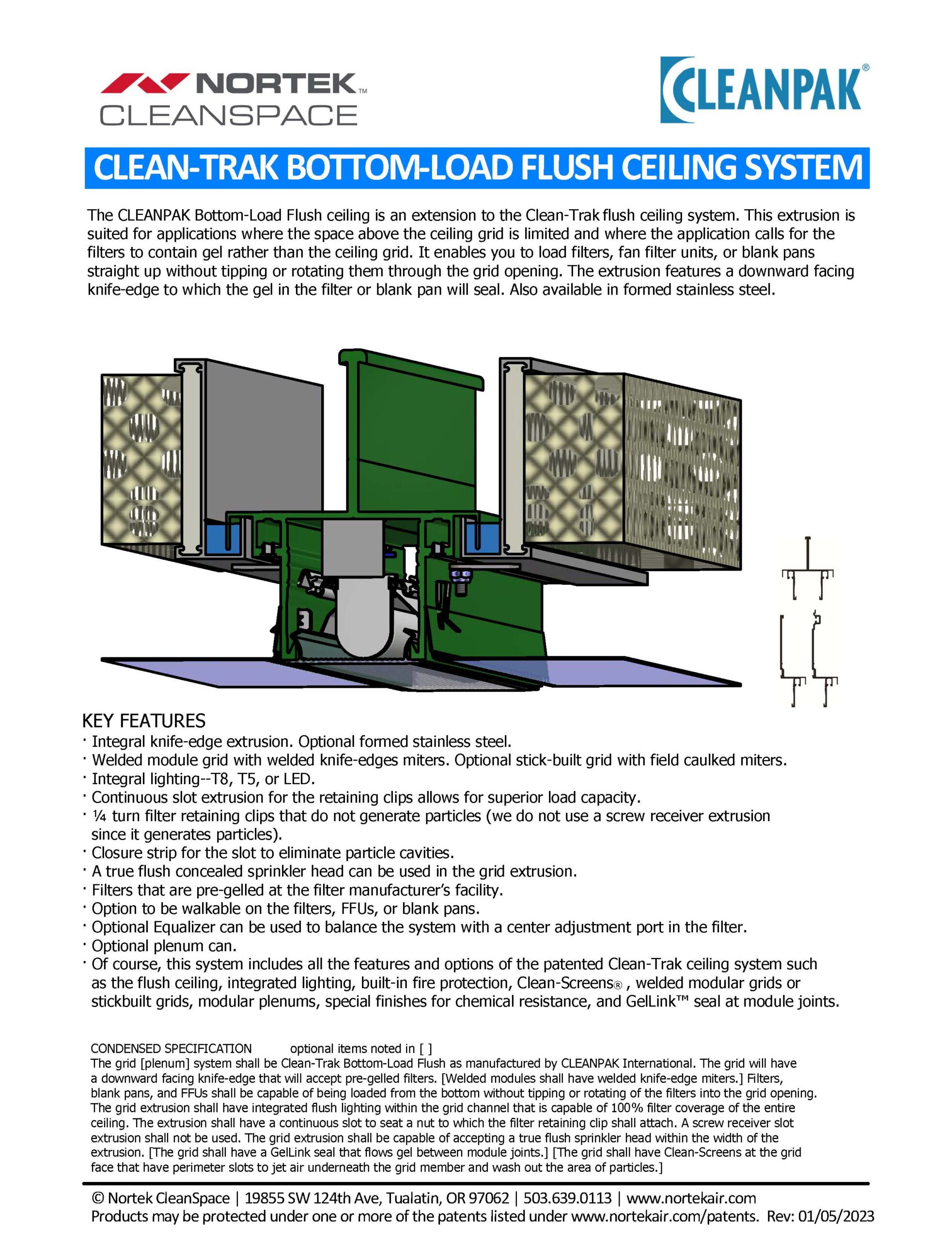

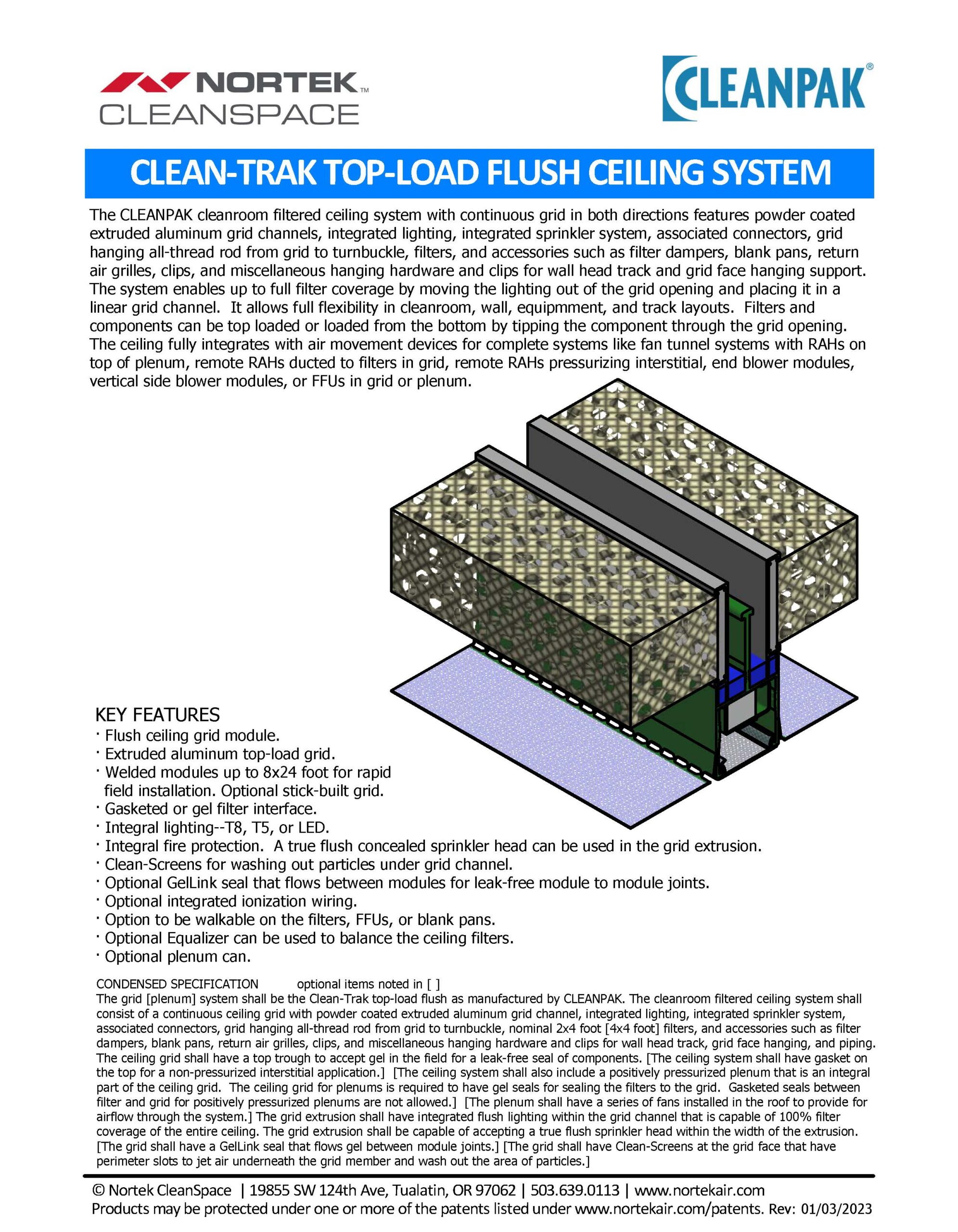

The Clean-Trak® modular flush-surface ceiling system is available in several versions, including modular top and bottom-load systems, gasketed and gel flush ceilings, with integrated lighting and fire protection.

Installed in thousands of cleanroom facilities, the Clean-Trak® modular flush-surface ceiling system has revolutionized the cleanroom industry. Operational in more than 20 million square feet of cleanroom ceilings, Clean-Trak is the worldwide standard providing the highest degree of unidirectional airflow and lowest turbulence of any integrated grid system.

CLEANPAK™ products offer the widest range of cleanroom ceiling systems to suit any semiconductor, pharmaceutical, aerospace, biotechnology, nanotechnology, research laboratory or life science requirement. We offer several versions of modular top and bottom-load systems, gasketed and gel flush ceilings with integrated lighting and fire protection, and for meeting clients’ off-site manufacturing needs.

Want to learn more?

Benefits

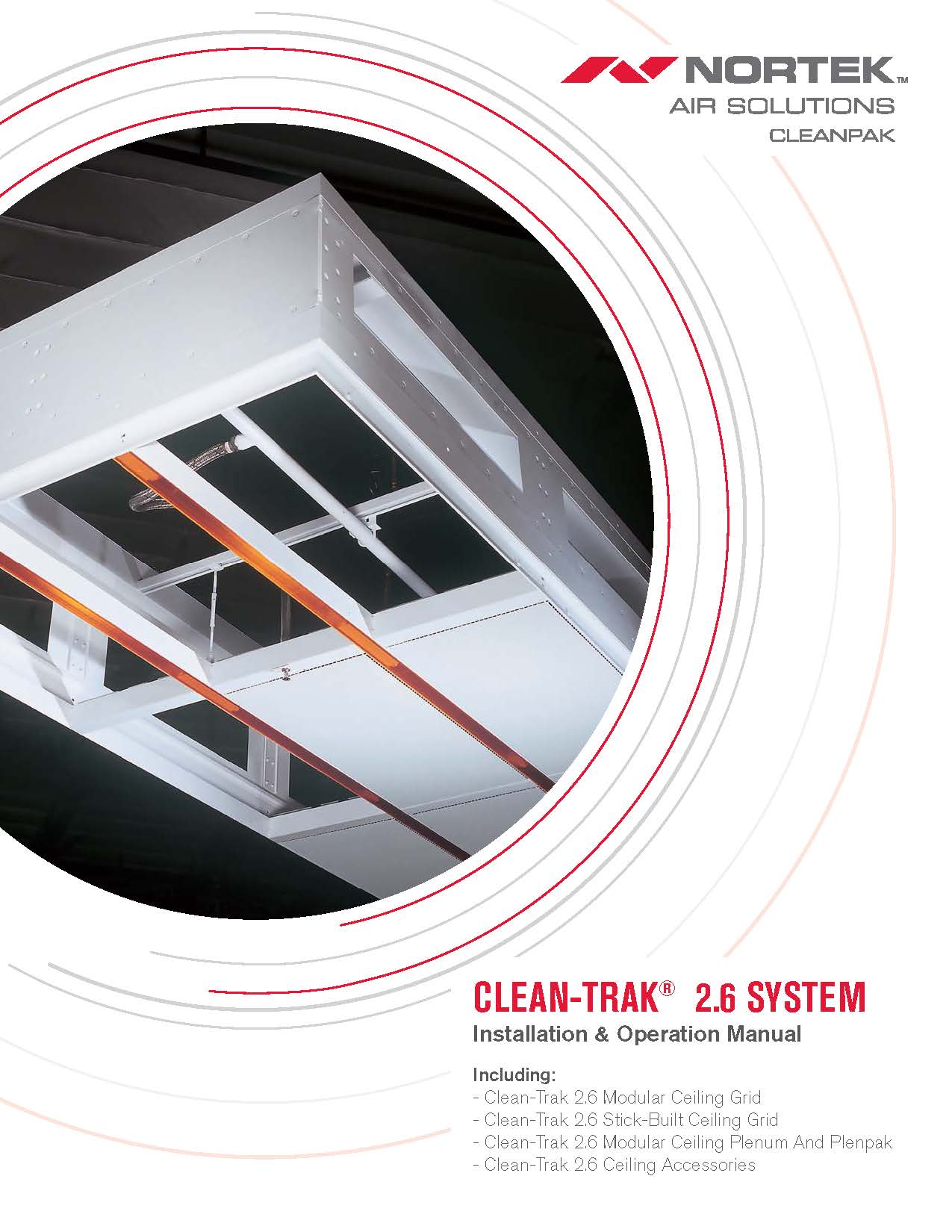

Clean-Trak Modular Grid

Modular grid with all components built in factory

Modules are lifted into place with sprinklers, lights, lenses, wiring and ionization wiring already installed

Significant on-site labor and time savings

Integrated LED lighting

Integrated fire protection system–hard-piped or FM approved flex hose

Top-load or Bottom-load filter systems

Optional GelLink module-to-module joint seal

Optional LED lighting troffers

Optional stronger grid profiles to handle high automated material handling system (AMHS) loads and high suspended loads

UL listed

Featuring

Solid Welded Pressure Plane

Clean-Screens

Sealed Grid Penetrations

Hanging Hardware

Wall Blank-Offs

Walkable Blank Pans/Filters/Return Grills

Superior Flexibility