Servicor Stretchwall Cleanrooms stand out as the most structurally rigid available anywhere in the industry, helping you satisfy local building code. We offer custom sizes and heights to meet your needs. All Servicor frames and ceiling grids are powder coated to ensure truly non-outgassing components. Servicor’s exclusive walkable Uni-Grid ceiling system is comprised of fully welded steel, and when assembled with wall frames, it forms a structurally sound self-supporting system. An added benefit is the ability to maintain pressure control as needed for various applications, which is especially important for cleanrooms located near a door or rollup door, nearly eliminating the possibility of outside air entering the room. Stretchwall cleanrooms are ideal for packaging rooms, packaging inspection, material handling/shipping and receiving, injection molding, and more. Industries served include medical device manufacturing, aerospace, automotive, and others.

FEATURES AND BENEFITS

Economical alternative to Hardwall panel construction.

Exclusive Uni-Grid™ load-bearing, walkable ceiling system allows for easy maintenance and interchange of lights, tiles and HEPA filters.

Available in an unlimited number of sizes and configurations using high quality standard components.

Baked polyurethane powder coat finish ensures non-outgassing components with a hard-shell finish that will withstand frequent cleansing and will not contaminate your process.

Truly modular, non-progressive construction provides maximum flexibility to accommodate new processes and equipment.

Fast installation, simple to relocate, and pre-engineered to meet your demanding schedule.

Structural Integrity

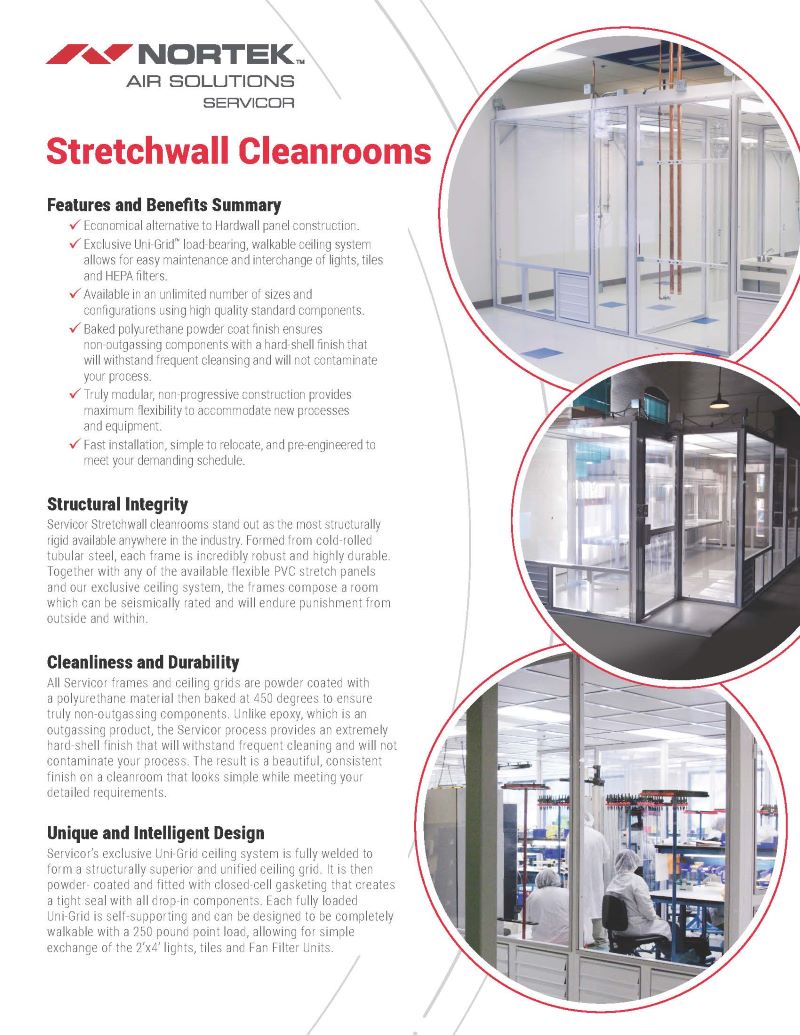

Servicor Stretchwall Cleanrooms stand out as the most structurally rigid available anywhere in the industry. Formed from cold-rolled tubular steel, each frame is incredibly robust and highly durable. Together with any of the available flexible PVC stretch panels and our exclusive ceiling system, the frames compose a room which can be seismically rated and will endure punishment from outside and within.

Cleanliness and Durability

All Servicor frames and ceiling grids are powder coated with a polyurethane material then baked at 450 degrees to ensure truly non-outgassing components. Unlike epoxy, which is an outgassing product, the Servicor process provides an extremely hard-shell finish that will withstand frequent cleaning and will not contaminate your process. The result is a beautiful, consistent finish on a cleanroom that looks simple while meeting your detailed requirements.

Unique and Intelligent Design

Servicor’s exclusive Uni-Grid ceiling system is fully welded to form a structurally superior and unified ceiling grid. It is then powder- coated and fitted with closed-cell gasketing that creates a tight seal with all drop-in components. Each fully loaded Uni-Grid is self-supporting and can be designed to be completely walkable with a 250 pound point load, allowing for simple exchange of the 2’x4’ lights, tiles and Fan Filter Units.

Specifications

Size: Innumerable configurations, in standard increments of 2’x4’ units; unsupported spans up to 48’ with truss system.

Class: Federal Standard 209e Class 100,000 to Class 100 and ISO 9-5 Standards compatible.

Filtration: 2’ x 2’, 2’ x 3’, and 2’x4’ HEPA or ULPA Fan Filter Units or Ducted Terminal HEPA. Complete FFU control systems available.

Ceiling: Uni-Grid™ ceiling system: 11ga thick steel , all-welded construction, fitted with closed-cell gasketing.

Frames: Welded 2”x 2”x.083” heavy gauge cold-rolled tubular steel, pre-engineered construction.

Finish: White baked polyurethane powder-coating.

Finish: 16 mil clear flexible PVC standard.

Options

Factory installation of provided items.

Stretch panel materials include: clear, static dissipative, UV protectants, opaque white, black, as well as other application-specific materials.

UL listed flush-mount electrical outlets and light switches.

Pass-thru’s, air-showers.

Teardrop or flow-through lighting.

Cutouts to accommodate processes, conveyer belts and machinery.

Structural calculations and seismic ratings.

Integrated anteroom.

Door Interlock Systems.

Swing doors, automatic sliding doors, automatic roll-up doors, sliding track curtains or strip access entrances.