Cutting-Edge Air Handlers for High School Expansion

At A Glance

BACKGROUND: The historic Battle Creek Central High School campus in Battle Creek, Michigan, was renovated and expanded to meet the changing educational needs of students.

ISSUE: The school district needed to achieve long-term energy efficiency to minimize operating expenses while meeting unique air handling requirements, such as providing large volumes of outdoor air for required classroom ventilation and dehumidification for the pool area.

SOLUTION: Fourteen custom EnergyPack® Air Handlers with AHRI-Certified™ enthalpy wheels or plate heat exchangers were used to meet the school’s air handling needs. Air handlers with high output, a distributed design, and a geothermal system were used to solve the unique project challenges.

RESULTS: After operating through both heating and cooling seasons, the Venmar EnergyPack units are running “as well as a Swiss watch” according to the school’s facility director. Heat pumps utilize groundwater as the heatsink and provide the school with simultaneous heating and cooling throughout the year.

A high school in Battle Creek, Michigan, recently underwent a major transformation from an aging 1908 building to a facility that embodies the newest principles of educational design, including an HVAC plant with sparkling efficiency and flexibility. The facility upgrade was accomplished on a tight schedule that minimized disturbance to the educational mission.

After operating through both heating and cooling seasons, the Venmar EnergyPack units are running “as well as a Swiss watch” according to the school’s facility director.

Equipment

Fourteen custom EnergyPack® Air Handlers with AHRI-Certified™ enthalpy wheels or plate heat exchangers were used to meet the school’s air handling needs.

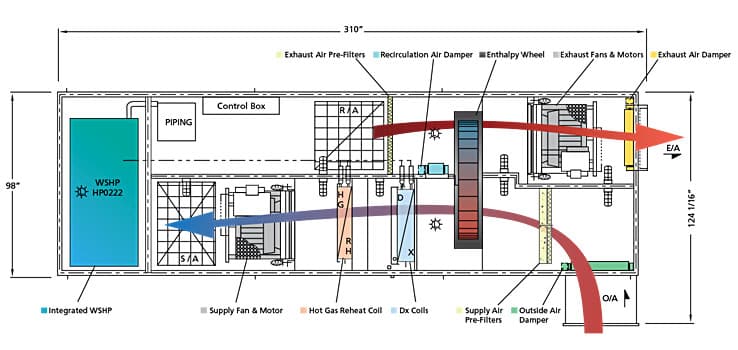

Elevation view of a 9,000 cfm Energy Recovery System Air Handler with enthalpy wheel and integrated 44-ton, ground-source heat pump, shown in summer operating mode.

KEY POINTS

- Battle Creek Central High School used 14 Energy Recovery System Air Handlers in its renovation and expansion project.

- Primary considerations were achieving maximum energy efficiency, while retaining as much of the high school’s historic structure as possible.

- The large air handler units and distributed design of the air handlers allows for large volumes of outdoor air for classroom ventilation, dehumidification for the pool area, and simultaneous heating and cooling.

- A geothermal system was employed to reduce the school’s energy usage, while meeting high standards for building air quality.