Enjoyable Environments for the People Who Use Your Building

Hospitality and amusement facilities—ranging from hotels to spas, and stadiums to entertainment venues—have unique, demanding requirements. In these types of buildings, occupancy can vary greatly from one minute to the next, resulting in tremendous variance in the cooling, ventilation, and humidity demands in different spaces. In performance halls, stadiums, and concert venues, sound levels and comfort are a primary concern. In swimming pools and water parks, constant humidity control is required. Nortek Air Solutions has developed innovative custom HVAC solutions for the full range of hospitality and amusement applications.

Understanding Hospitality & Amusement HVAC Challenges

-

Energy Efficiency

-

System Maintenance and Reliability

-

Indoor Air Quality

-

Temperature Control

-

Integration with Building Management Systems

-

Guest and Staff Satisfaction

-

Technological Advancements

-

Cost Management

-

Regulatory and Compliance Issues

Transformative Power of Air…

…is what we believe in at Nortek Air Solutions. Everyday, each of us breath 23,000 times. As much as we depend on air, it is often the one most taken for granted. The nearly 2,000 passionate entrepreneurs that fuel Nortek Air Solutions, it’s at the heart of everything we do. We believe in the transformative power of air and creating a safer, healthier, and more productive world together.

Energy Efficiency…

… can be a high priority in hospitality and amusement buildings because often they have high energy consumption, making energy efficiency a critical concern to manage operational costs. There is increasing pressure to adopt sustainable practices, including the use of energy-efficient HVAC systems and renewable energy sources. Nortek Air Solutions can provide ideas for improving fan performance, reduce energy consumption, lower airside leaks, and create more sustainable designs.

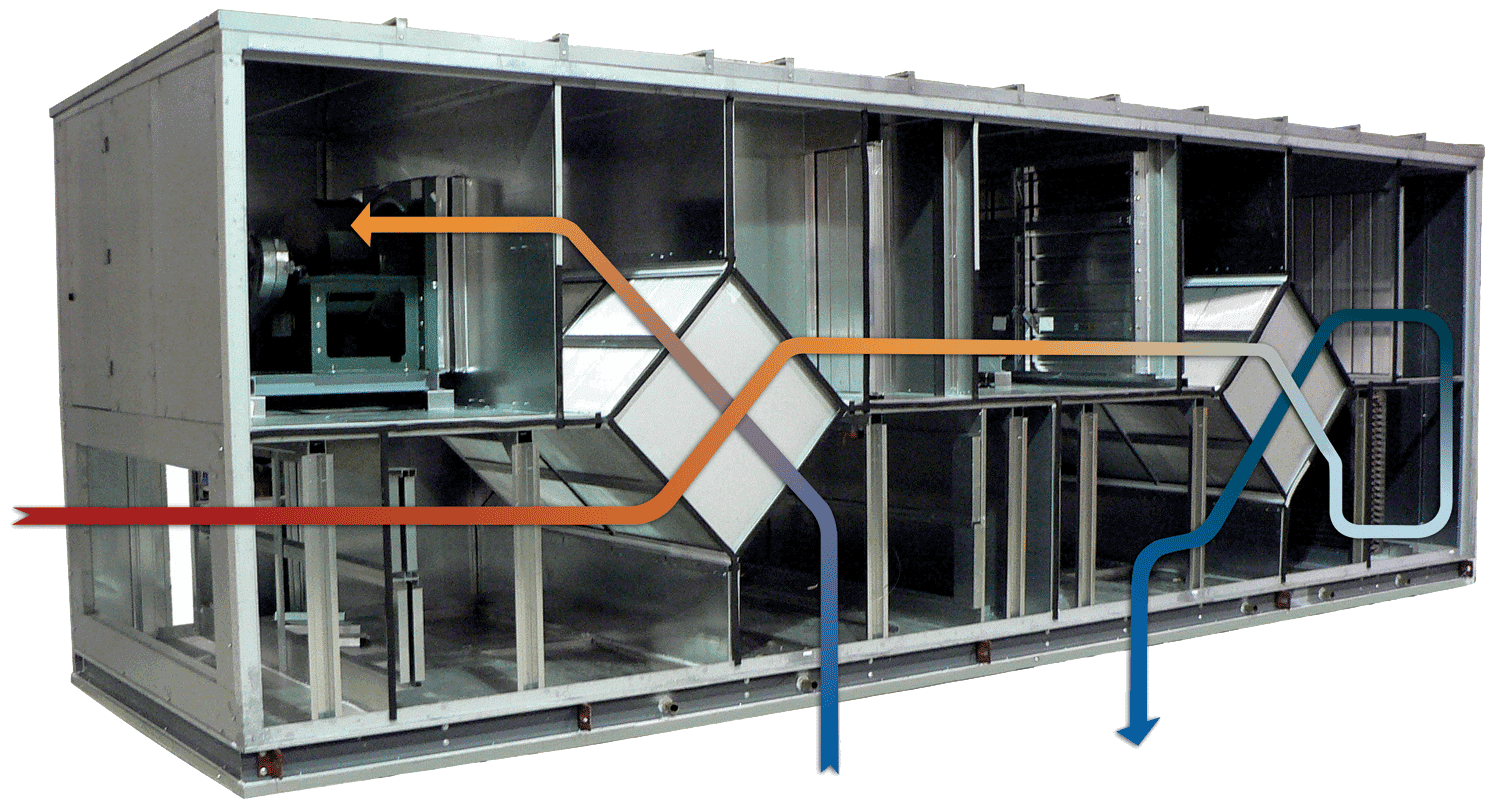

Lower Energy Costs with Energy Recovery…

Our Dedicated Outdoor Air Systems (DOAS) can significantly enhance buildings in several ways. DOAS provides consistent and controlled ventilation, ensuring that fresh air is continuously supplied to occupied space. DOAS also aids in pollutant removal by effectively removing indoor pollutants such as carbon dioxide, volatile organic compounds (VOCs) and other contaminants. DOAS helps maintain a healthier environment for guests and staff. Our DOAS products are designed to condition and supply 100% outdoor air to your building spaces.

Reduce Energy Demand…

…with evaporative-cooled condensers in our packaged DX products. You can often reduce the footprint of a unit due to the increase in efficiency in condensing. In comparison with an air-cooled condenser, an evaporative condenser requires less coil surface and airflow to reject the same heat, and greater operating efficiencies can be achieved by operating at a lower condensing temperature.

Also, evaporative-cooled condensing can reduce the electric service required for the unit. It gives designers an option to increase the capacity of a unit when replacing an existing air-cooled unit without increasing the electric service to the building.

Good Indoor Air Quality…

…is crucial for guest health and comfort, particularly in enclosed spaces. Meeting health and safety regulations regarding air quality means managing humidity levels to prevent mold growth and maintain comfort. Maintaining consistent and comfortable temperatures in various areas, including guest rooms, common areas, and event spaces. Different areas may require different temperature settings, complicating system management. Adjusting systems to handle seasonal changes in temperature and occupancy levels.

Keeping Indoor Air Clean…

…in air handling systems to control air quality and reduce airborne pathogens is critical in most facilities. Maintaining strict hygiene, sanitation and maintenance standards can help prevent the spread of infections. Nortek Air Solutions provides a variety of advanced filtration technologies to aid in achieving your filtration needs. Technologies like High-Efficiency Particulate Air (HEPA) filters, Ultra-Low Penetration Air (ULPA) filters, activated carbon filters, gas phase filters, medium efficiency pleated filters, high efficiency bag filters and high efficiency rigid filters.

Special configurations…

…of air handlers is our specialty. Unique dimensions and shapes are reasons customers seek a custom solution from Nortek Air Solutions. We offer custom sizes ranging from very small 2000 cfm to over 400,000 CFM, 20 to 400 tons, with complex configurations (double/triple wide, double/triple stack, L-shaped, U-shaped).

Assured Acoustics…

…can be achieved from innovative solutions for sound control and noise reduction to eliminate excess noise and distractions in your educational facility. Innovations like our Passive Noise Control (PNC) shown here used in a symphony hall to reduce inlet sound power.

Our commitment to customer satisfaction is evident at the Nortek Air Solutions Acoustics Test Lab. It is one of the largest, AMCA 310 Accredited, fully equipped, dual reverberant chamber HVAC testing facilities of its kind. We have created decades of modelling experience and have become a trusted source of sound and vibration data for our customers.

The laboratory provides a wide range of unique services to our customers including acoustical modeling, comprehensive production testing, and robust performance and diagnostic analysis. It also serves as a site for rigorous, ongoing research and development testing and modeling, as well as a showplace for customer-witnessed testing of airflow, thermal, vibration and acoustical performance of units manufactured by Nortek Air Solutions.

The lab is designed and equipped to perform simultaneous testing in accordance with AMCA Standard 300 for Sound Power Levels and AMCA Standard 210 for Airflow Performance.

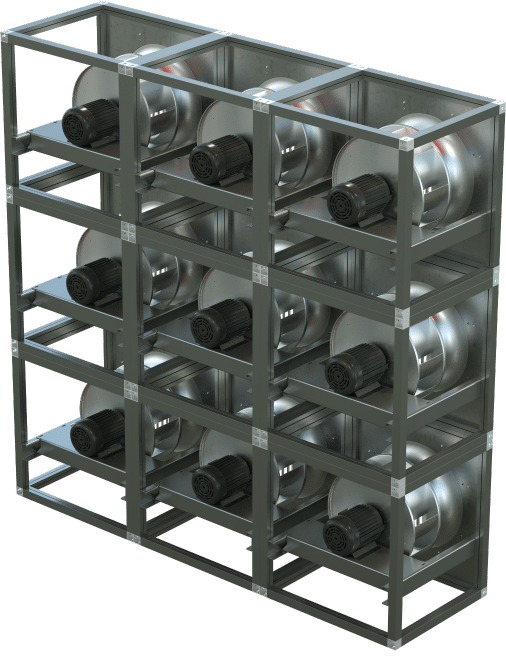

Knockdown Air Handlers…

…with FANWALL TECHNOLOGY allow you to replace aging or end-of-life air handlers with even the most severe access limitations. Knockdown units are fully assembled to verify fit and function at the factory. They are then sent to the site for disassembly, or they can be disassembled at the factory into sections or components (down to the piece part) before being palletized for delivery to the jobsite. Each delivered component is numbered and labeled according to detailed assembly drawings for reassembly at the jobsite. Options for factory supervision of the rebuild and contractor training further enhance the rebuild process at the jobsite.

Natatoriums…

… generate significant amounts of moisture from the pool water, leading to high humidity levels. Excessive humidity can cause condensation on walls, windows, and other surfaces, potentially leading to structural damage and mold growth.