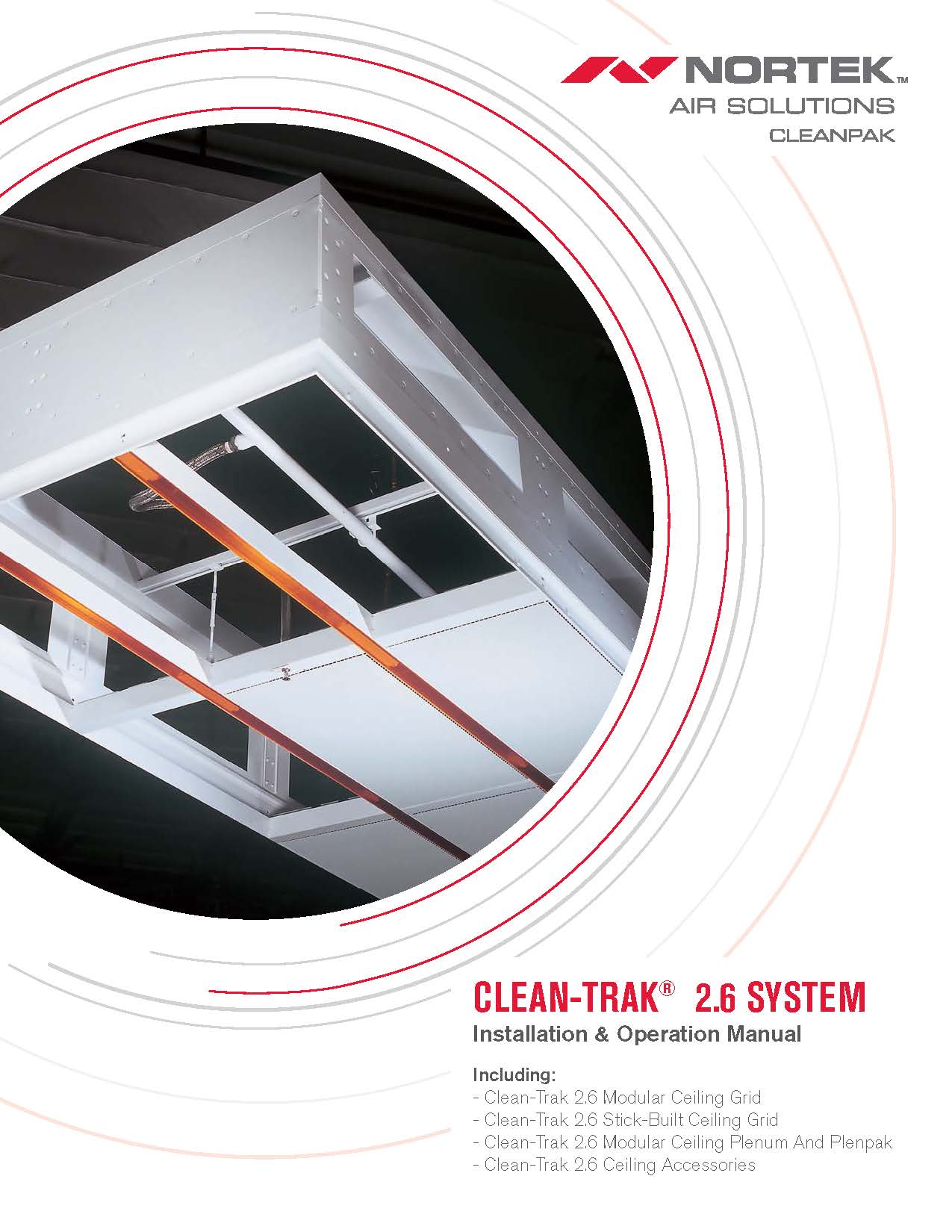

Clean-Trak Plenums are utilized to minimize transverse ducts and duct collars while reducing overall pressure drop, and are available with side-wall openings so one fan module can be shared with multiple plenums.

Clean-Trak Plenums are utilized to minimize transverse ducts and duct collars while reducing overall pressure drop. These plenums offer the benefits of Clean-Trak flush ceiling grid, including integrated lighting and fire protection, as well as Clean-Trak’s superior performances.

Structurally, Clean-Trak Plenums support high point loads with minimum deflection. This allows the system to support a fan module, live loads and process accessories. Walkable top skins make maintenance easy by allowing quick access to the fan module.

Plenums are available with side-wall openings so one fan module can be shared with multiple plenums. We can make them ducted from the fan deck if required for special applications. Our Laminar Flow performance can meet the highest levels of HEPA and ULPA filtration required in the industry, and positive/ negative pressure requirements. Unidirectional air flow is achieved within a few inches of discharge screens with our unique Flush Grid design and can be maintained at the work surface even in high ceiling areas.

Benefits & Features

Support high point loads with minimum deflection

Available with side-wall openings

Welded construction with walkable top skins

Powder coated for easy cleaning and non-particulation

Integrated sprinkler system with optional fully concealed head

Optional PlenPAKTM fan powered plenums

Optional cooling coils

Top-load or bottom-load filter grid

Gel grid for pressurized plenums

Gasketed grid for plenums with negative pressure with FFUs

Optional Equalizer for air distribution inside plenums

Optional GelLink module-to-module joint seal

Optional GelShare shared-air opening seal

Integrated flush lighting systems