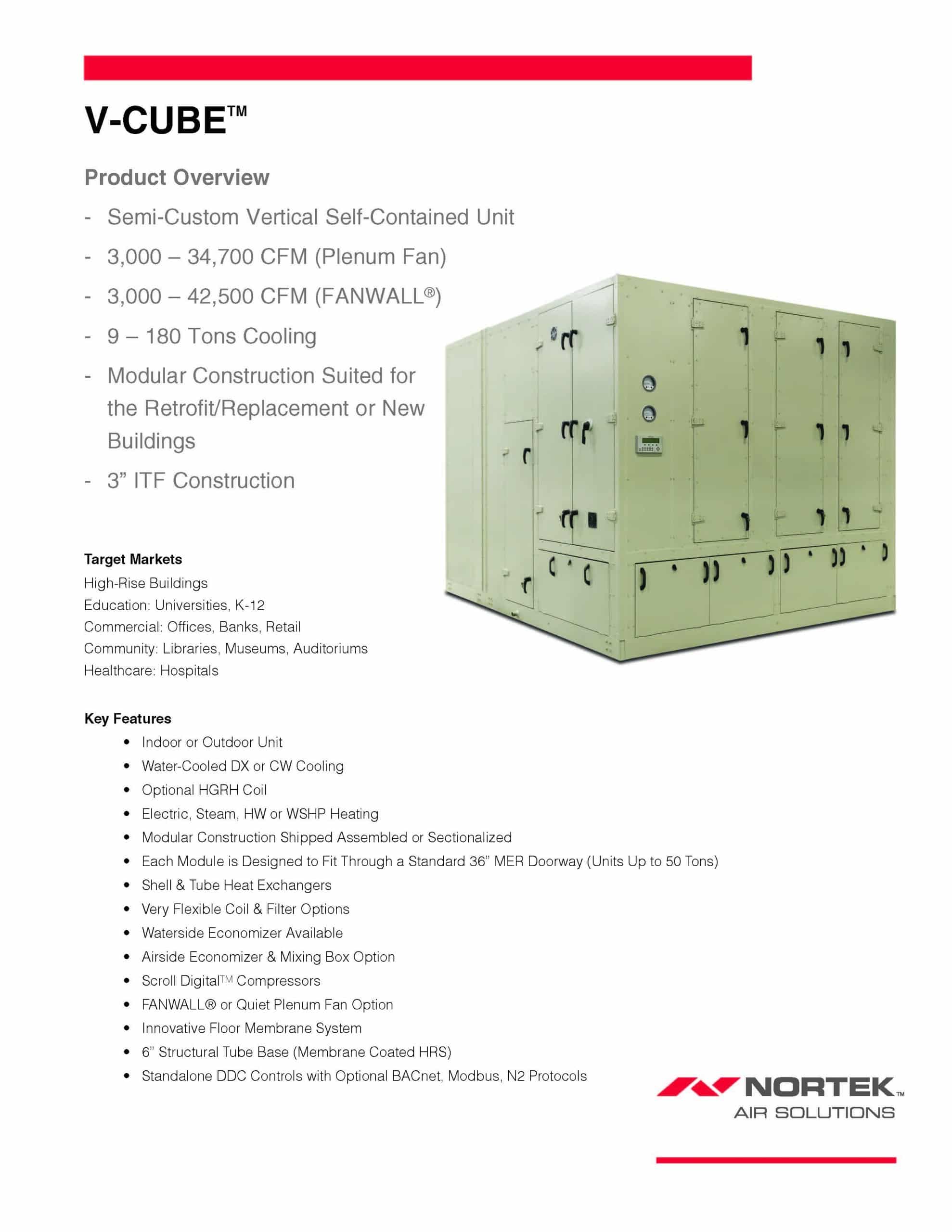

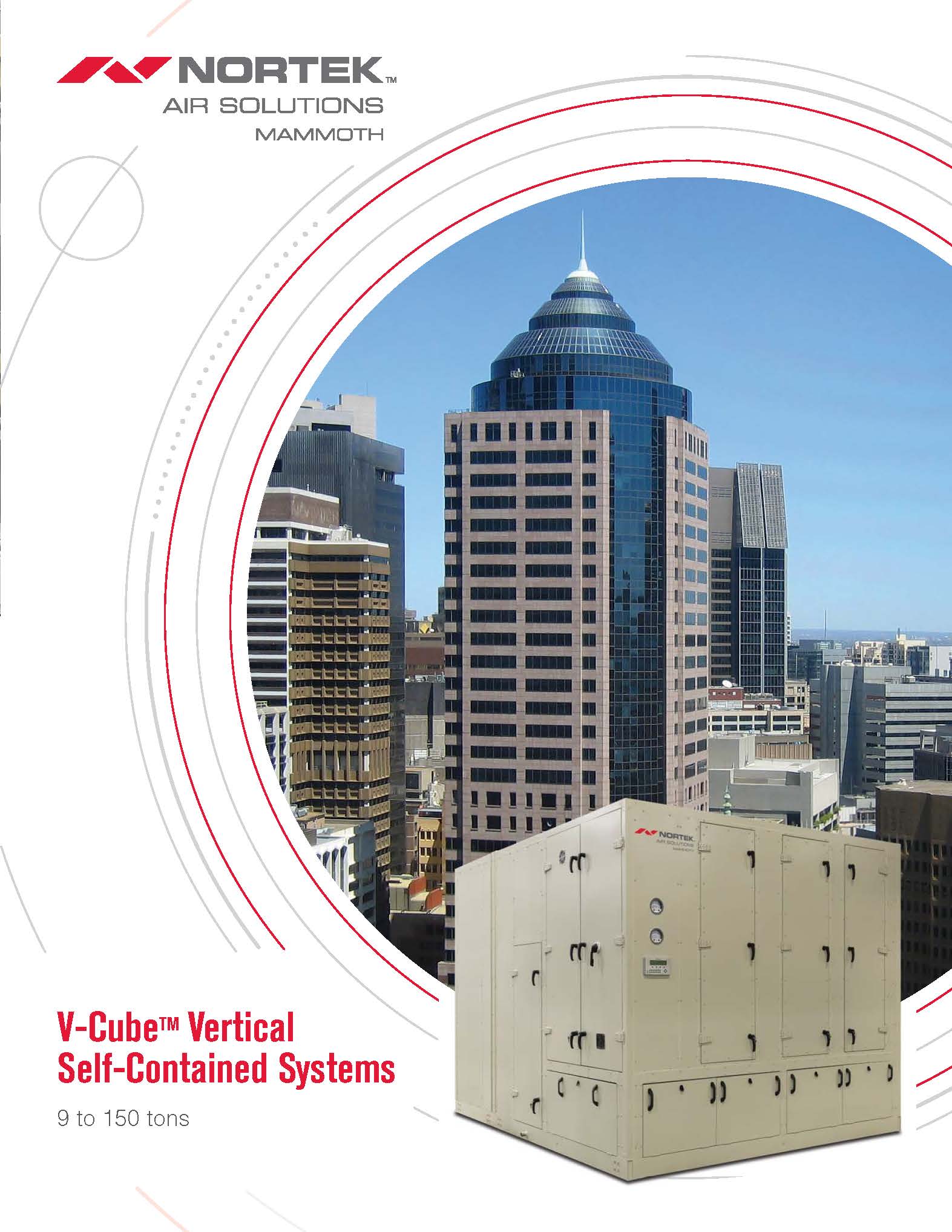

Floor-by-Floor Air Handling in New Construction or Retrofit Applications — 9 to 150 tons, 4,000 to 40,000 cfm

Our V-Cube Vertical Self-Contained Systems are famous for their quiet operation, compact design, and flexible configurations, making them an ideal solution for buildings of every type and size. Featuring a range of capacities and airflow, configurations, coil and filter options, exceptionally quiet and efficient fan options — including FANWALL TECHNOLOGY® — and additional features to improve your system’s performance, increase energy efficiency, or reduce sound levels, each V-Cube is custom designed and built to meet your project requirements. The compact footprint reduces the unit’s space requirements, and our knockdown capability allows the unit to fit through standard 3-foot doorways and in service elevators. Additionally, the unit features independent refrigerant circuits, an easy maintenance design, and the EPiC™ system controls which work with the BACnet® communication protocol.

Benefits

Flexibility

9 to 150 tons capacity and 4,000 to 40,000 cfm airflow to match your application requirement.

Configurations include direct expansion (DX) with air cooled, water cooled, or glycol cooling; steam, hot water, or electric heat; airside or waterside economizer; and chilled water air handler.

Side, top, or down discharge for use in underfloor applications.

Flexible coil selections up to 10 rows, allowing use in a variety of applications, including low air temperature.

Multiple filter options including optional MERV13, 4-inch final filters with 2-inch pre-filters to provide superior indoor air quality.

Quiet Operation and Compact Footprint

Compact footprint reduces interior space requirements and allows for easier unit replacement.

Knockdown capability allows unit to fit through standard 3-foot doorways and in service elevators.

Exceptionally quiet operation allows units to be placed adjacent to occupied spaces and can reduce attenuation costs. Coplanar Silencers® are available for enhanced acoustic performance.

High-Quality Construction

Integrated Thermal Break Framing™ (ITF) cabinet construction for industrial-grade, high-sealing integrity.

Airtight and watertight floor membrane to improve leakage characteristics and minimize sound transmission.

3-inch R12.9 insulation in the walls, roof, and doors, a welded base frame (6-inch structural tubing perimeter), and double-seal thermal break doors.

Easy maintenance design, including unit tooled access panels, cleanable-in-place shell and tube condenser, and a dual sloped, stainless steel drain pan.

Energy Efficiency

Multiple coil and compressor combinations. Shell and tube condensers to minimize condensing temperatures and water pressure drop.

Variable Frequency Drive (VFD) selections for VAV operation allow efficiency to be optimized for each specific application.

Waterside economizer option provides the ability to take maximum advantage of free cooling opportunities to reduce energy consumption.

Multiple Fan Options, Including FANWALL Technology

FANWALL TECHNOLOGY increases the efficiency, quiet performance, and reliability of your system

FANWALL TECHNOLOGY consists of an integrated system of state-of-the-art fans, efficient motors, controls, and accessories matched to your air handling requirements

Eliminates belt, sheave, and bearing maintenance