We offer water replacement coils for cooling, heating, and general heat transfer applications with water or thermal fluids such as ethylene or propylene glycol.

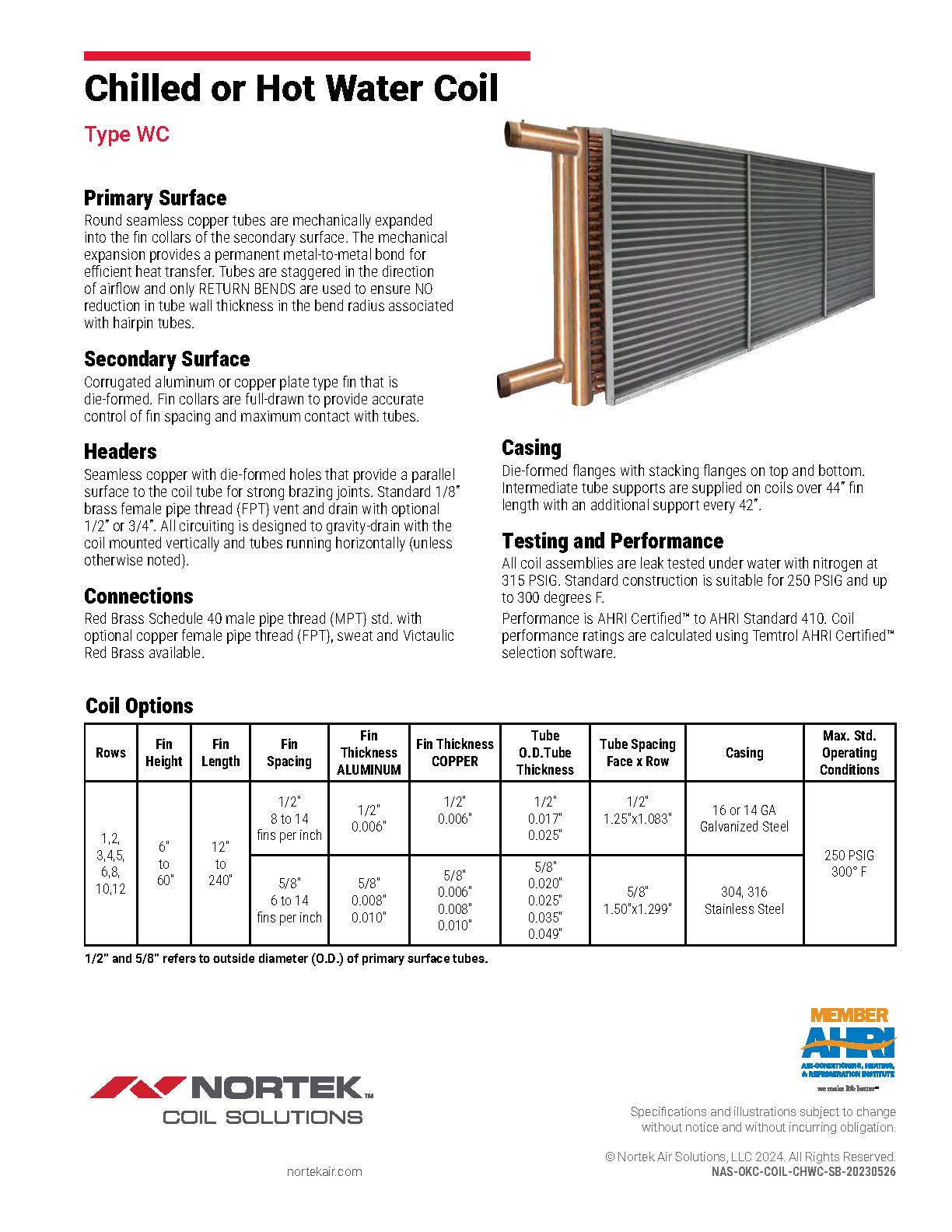

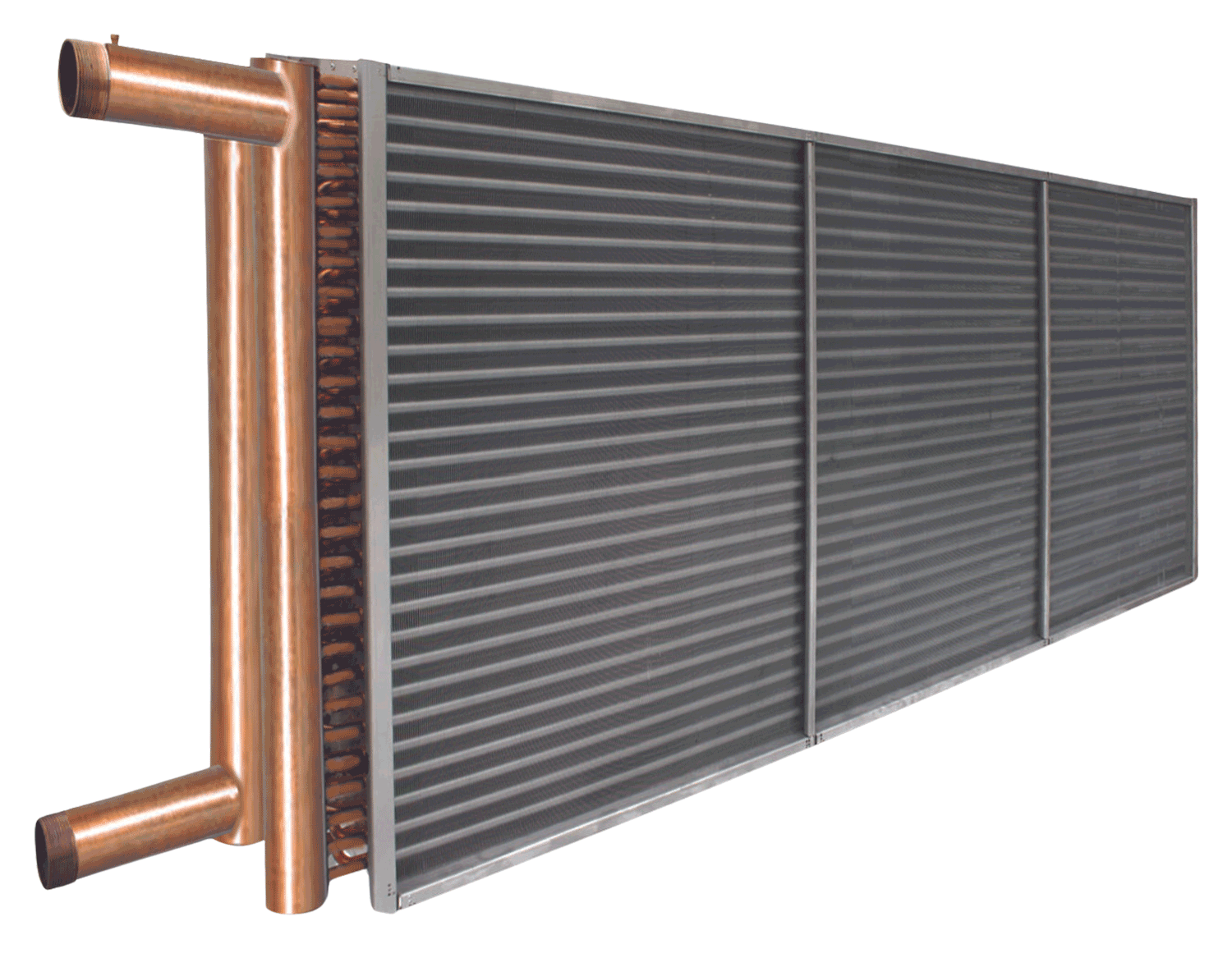

CHILLED OR HOT WATER COIL - TYPE WC

Primary Surface

Round seamless copper tubes are mechanically expanded into the fin collars of the secondary surface. The mechanical expansion provides a permanent metal-to-metal bond for efficient heat transfer. Tubes are staggered in the direction of airflow and only RETURN BENDS are used to ensure NO reduction in tube wall thickness in the bend radius associated with hairpin tubes.

Secondary Surface

Corrugated aluminum or copper plate type fin that is die-formed. Fin collars are full-drawn to provide accurate control of fin spacing and maximum contact with tubes.

Headers

Seamless copper with die-formed holes that provide a parallel surface to the coil tube for strong brazing joints. Standard 1/8” brass female pipe thread (FPT) vent and drain with optional 1/2” or 3/4”. All circuiting is designed to gravity-drain with the coil mounted vertically and tubes running horizontally (unless otherwise noted).

Connections

Red Brass Schedule 40 male pipe thread (MPT) std. with optional copper female pipe thread (FPT), sweat, and Victaulic Red Brass available.

Casing

Die-formed flanges with stacking flanges on top and bottom. Intermediate tube supports are supplied on coils over 44” fin length with an additional support every 42”.

Testing and Performance

All coil assemblies are leak tested under water with nitrogen at 315 PSIG. Standard construction is suitable for 250 PSIG and up to 300 degrees F.

Performance is AHRI Certified™ to Standard 410. Coil performance ratings are calculated using Temtrol AHRI Certified™ selection software.