Flexible Air Handling Solutions for the Ideal Manufacturing Environment

Manufacturing and industrial facilities have unique HVAC requirements that need sophisticated solutions. Nortek Air Solutions designs and manufactures reliable, efficient custom HVAC systems for a wide range of industries—including mining, circuit board manufacturing, pharmaceuticals, and food and beverage—as well as systems for cleanroom environments.

Understanding Industrial HVAC Challenges

-

Large Spaces and High Ceilings

-

Diverse Environmental

-

Requirements

-

High Heat Loads

-

Ventilation and Air Quality

-

Energy Efficiency

-

Maintenance and Durability

-

Compliance and Safety

-

Integration with Other Systems

Maintaining consistent temperatures across vast areas can be difficult. High ceilings can lead to stratification, where warm air rises and cooler air stays at floor level. Ensuring even air distribution throughout the space requires sophisticated ductwork and powerful fans.

Scale…

…is the first competency Nortek Air Solutions excels in. Unique dimensions are one reason customers seek a custom solution. We offer custom sizes ranging from very small 2,000 cfm to over 400,000 CFM, 20 to 400 tons, with complex configurations (double/triple wide, double/triple stack, L-shaped, U-shaped).

Material Choices…

…are a second factor in why customers like working with Nortek Air Solutions. Depending on application needs, materials can include all-aluminum for weight considerations or stainless steel for corrosive environments. Material and component coatings, such as powder-coated metal, are available to help protect and extend the life of your investment.

Life Expectancy…

…is a third factor to consider when working with a custom manufacturer. Our custom units often last twice as long as commercial-grade units (20-30 years vs. 10-15 years). Nortek Air Solutions performs rigorous testing with outside testing and rating agencies like HCAI’s OSP, Miami-Dade Product Control, IBC Seismic, AMCA and ETL, to name a few. The photo shows one of our air handlers on a shaker table that simulates what a unit would see during an earthquake. The unit is filled with components typically found in an air handler so they can be evaluated during the testing.

These certifications ensure that our equipment meets high standards of performance and reliability, which is crucial in commercial settings where building environmental systems must remain active in the event of a natural disaster. They also help facilities comply with regulatory requirements and industry standards, reducing the risk of legal issues and penalties.

Performance…

…is the fourth reason more and more customers work with Nortek Air Solutions. We can handle high static pressure applications with low air leakage. Decades of acoustical testing and modeling enable us to provide acoustical data to match your conditions. requirements, and certifications (seismic, hurricane-rated).

Reliability, Redundancy and Maintenance-free…

…are high priority design factors in manufacturing facilities as they often can operate 24/7/365. In many industrial applications, a catastrophic failure of the HVAC system could lead to an interruption of normal operations and productivity. Nortek Air Solutions offers ideal solutions to help you maintain uninterrupted operations in your manufacturing facility.

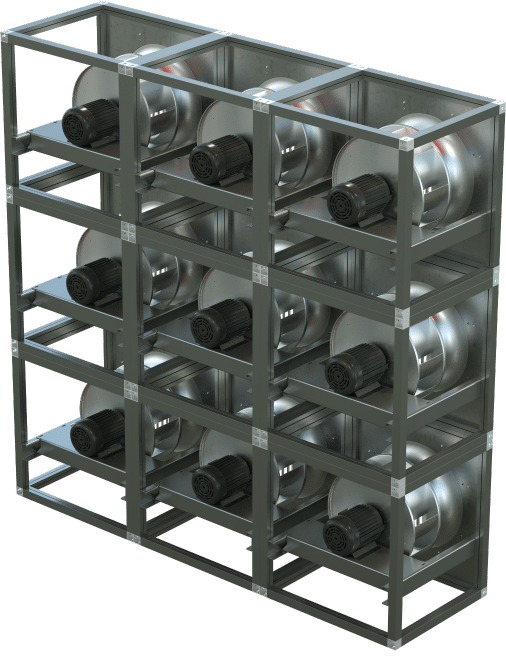

Multiple fan arrays in our patented FANWALL® Systems and multiple refrigeration circuits in some DX systems provide redundancy. Where N+1 redundancy is required, Nortek Air Solutions can deliver it in the smallest footprint and with the lowest electrical requirements.

With any system, maintenance can add up especially in large campuses. With FANWALL systems, there are no belts, sheaves and fan bearings to be adjusted or replaced. Replacement fan assemblies can be installed in 30 minutes or less and identical fan cartridges can be used for multiple units.

Large Heating Requirements…

… often requires balancing the heat generated by equipment with the need to keep workers comfortable. Nortek Air Solutions makes it easier in make-up air applications with our direct fired gas burner line. It is an ETL recognized component and features a rugged construction design made with cast aluminum headers and stainless-steel diffuser plates. Models are available with natural or propane gas.

Energy Efficiency…

… can be a high priority in industrial buildings because often they have high energy consumption, making energy efficiency a critical concern to manage operational costs. There is increasing pressure to adopt sustainable practices, including the use of energy-efficient HVAC systems and renewable energy sources. Nortek Air Solutions can provide ideas for improving fan performance, reduce energy consumption, lower airside leaks, and create more sustainable designs.

Cleanroom Environments…

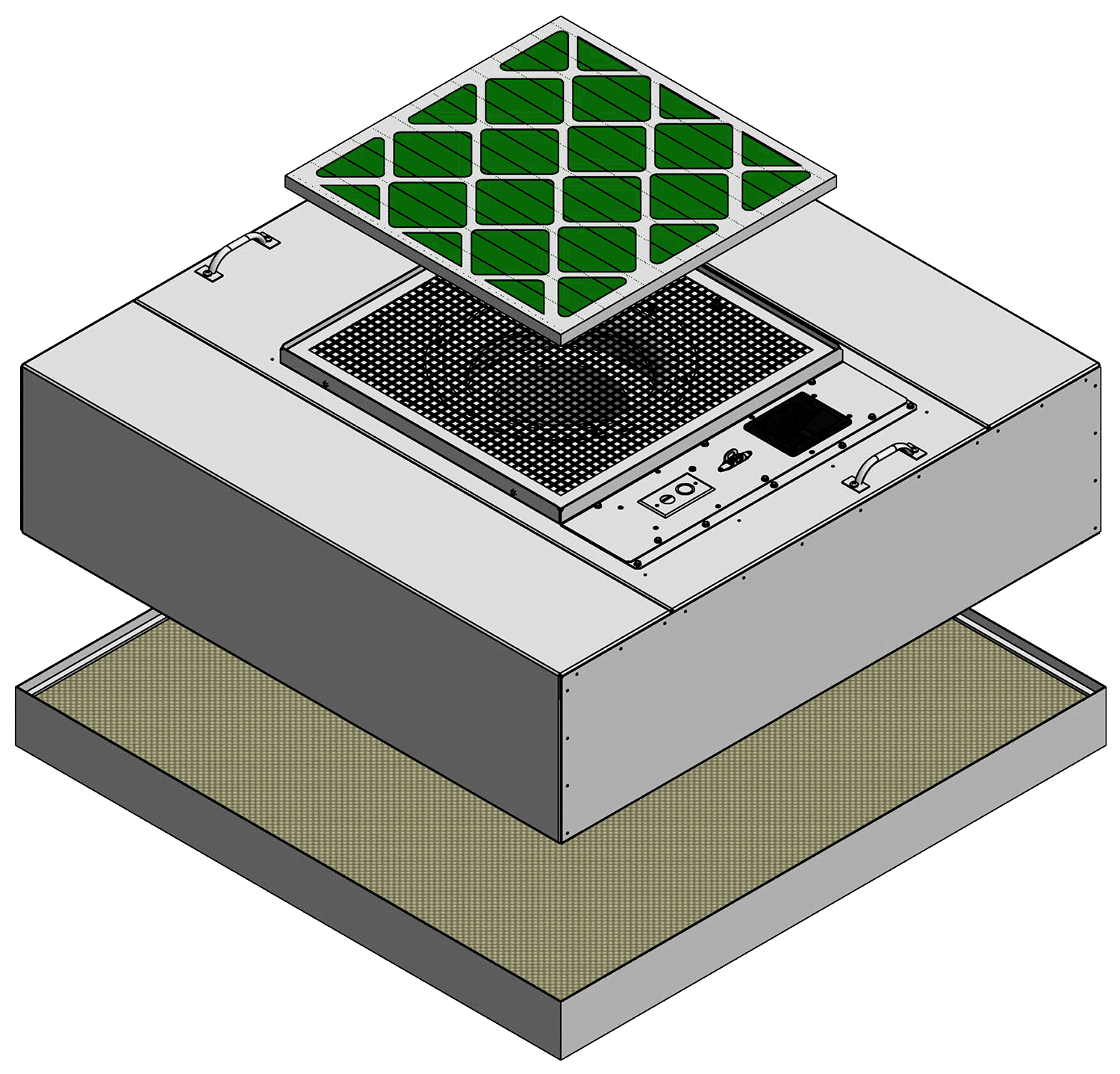

We offer a variety of Cleanroom Systems and solutions for manufacturing processes that require particle- and contaminant-free environments, including ceiling systems, modular cleanrooms, and laminar flow workstations.

Advancing Clean Environments…

...with over 20 years serving all types of clean environments, we have the experience to support every phase of aseptic cleanroom design and engineering construction. Our latest innovations include modular stainless steel flush ceilings that can be packaged with fan sections for low-profile Laminar Air Flow (LAF) applications. The custom design of CLEANPAK products offers a cost-effective combination of construction materials to fit your budget. Our reputation for engineering detail offers flexibility to meet the most complex fill finish layouts. Experience in the design and testing of hoods with different elevations, configurations and layouts provides us the capabilities to handle any type of project.